Tooling & Production

Make our engineers your engineers! We solve your complex tooling and production challenges by looking for the most creative, straightforward solutions. And what better way to accomplish that goal than to pair your team with a member of our talented engineering staff?

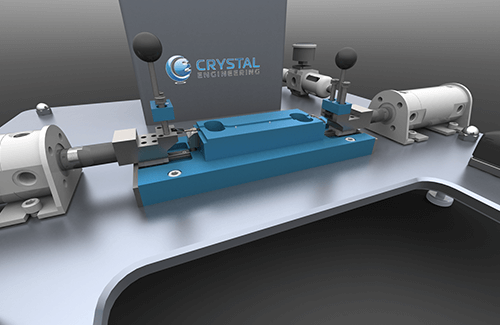

- Automated machines, mechanical fixtures, custom one-off designs? Yes, yes and yes. Highly skilled, educated, innovative and experienced, our engineers get their hands dirty, overseeing your project from the computer screen to the factory floor … on time, on budget and on point!

- Our engineers are certified in industry-leading 3D CAD software, such as Mastercam and Solidworks and Logopress.

- Need something original, unique, or specialized? Crystal offers engineered solutions ranging from quick turn prototyping to full scale production parts. We work directly with your team – from quote to concept to completion – producing answers to your specific needs and challenges.

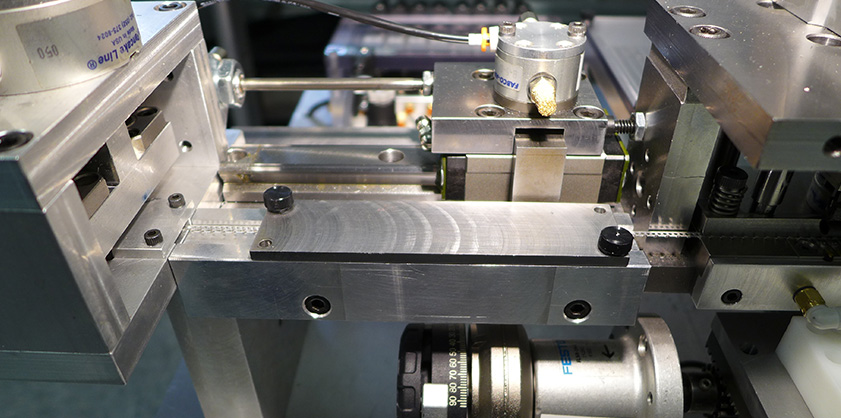

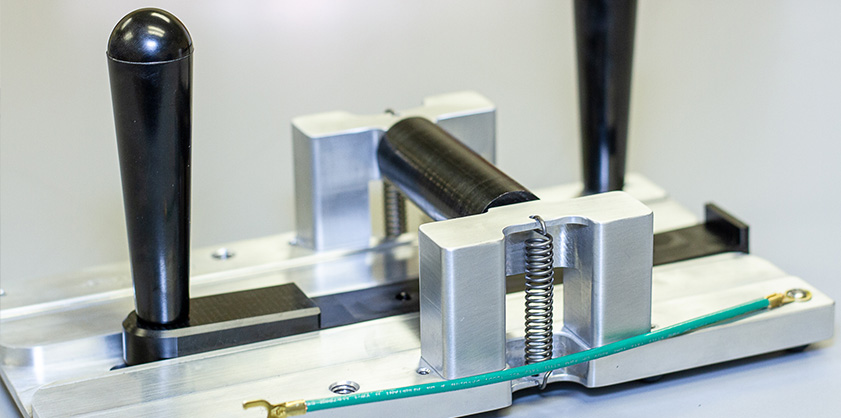

- Our tool-making team builds and designs dies and other factory floor solutions in-house, using the same machines we use in our production. We hone our skills making equipment for the plant, then look for ways to make it work for our customers.

Incorporating Additive Manufacturing

Additive Manufacturing (AM), commonly referred to as 3D printing, is known for its use in rapid prototyping, but that’s just scratching the surface. AM technology has huge implications across the entire manufacturing industry. Below are some of the ways our Engineering Services division is using Additive Manufacturing (AM) to find opportunities for our customers.

With AM, traditional rules are thrown out the window, which can make Additive difficult for designers to fully leverage. Our engineers are MIT-trained Additive Manufacturing Professionals who fully understand and embrace this new design mindset. We take full advantage of AM technology to advance your products and processes.

Some examples of our Additive Manufacturing approach:

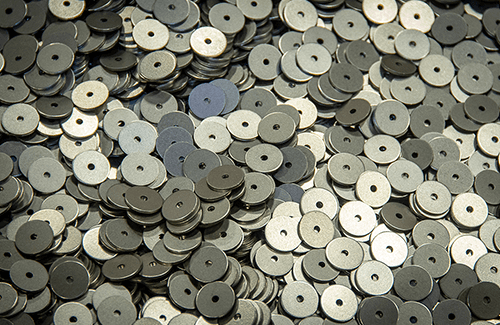

- Short Run Production - When production volumes are low, additive provides an affordable method for production without the expense for tooling or manufacturing requirements that drive up costs. We use AM for end use parts made of Nylon, ABS, Titanium, and Tool Steels, materials familiar to us and produceable using Additive.

- Rapid Prototyping - With AM, our engineers can produce functional prototypes in a matter of days, not weeks, and apply tweaks and revisions in real time. We can check our designs and get working prototypes into your hands quickly. This dramatically shortens the design cycle, reduces the costs of revisions, and gets your products to production faster.

- Assembly and Production Fixturing - We use AM in our production processes, and we can help you implement it in yours. AM allows for quick and cost-effective production of jigs and fixtures, customized for each product. Assembly aids, drill jigs, and robotic grippers are excellent applications for AM technology.

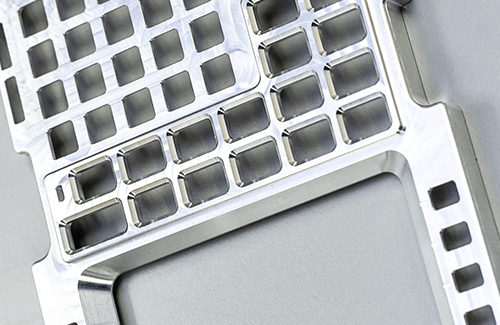

- CNC Machining Fixtures - We can quickly produce fixtures with AM that give our machine shop the edge in creating complex machined components in the most cost-effective way.

- Complex Geometries - With AM, complexity comes for free. That’s because integrating features that might be difficult or impossible to machine is of no consequence to the printer. Holes, hollow cavities, and lattice structures all reduce weight while maintaining the strength of the part. That translates to less material, less cost, and faster production time.