Precision Stamping

We make hard stamping simple.

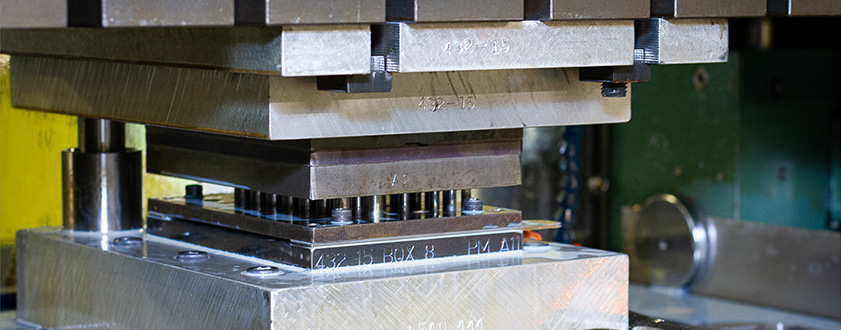

- We use Bruderer high speed presses (yes, the same Swiss-made presses Rolex uses) and we run them to their fullest capability, utilizing both precision and speed to maximize production.

- We use the highest grade raw materials – Tantalum, nickel-iron alloys, Monel, stainless, semi-precious metals, copper, and more.

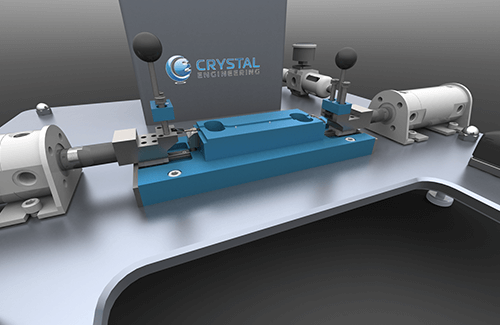

- We make the tools that make your products! Our design team will engineer dies to mass-produce custom solutions to your specifications. Our tailor-made progressive tools are capable of stamping out 17 parts in a single stroke.

- We ensure state-of-the-art precision and the tightest possible tolerances.

It may sound like overkill, the proverbial gun at a knife fight. But we figure our customers deserve the very best parts we can possibly manufacture, and we don’t want them sitting around waiting. We make them precise and we make them fast, and we get them into the hands of the people who need them. We keep moving to keep you from slowing down.

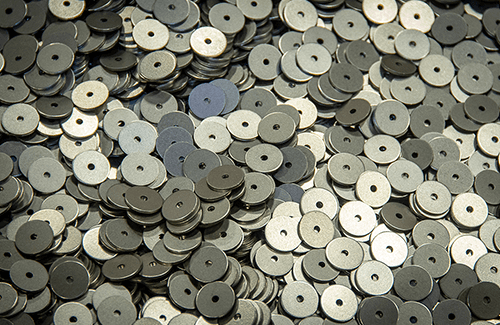

- High Speed department produces millions of SEMS Washers per day to support the automotive industry.

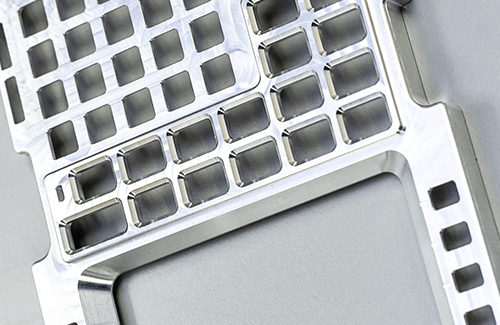

- Short Run produces hermetic microelectronic packaging for the electronics, aerospace, medical and defense industries.

- Used in the most advanced satellites, operating rooms, defense systems, and military vehicles.

- Coining, Draw work, Blanking, Forming, using compound and progressive tools.

- Thicknesses from .002 to .150.

- Speeds up to 1,200 strokes per minute.

- Up to 60 ton capacity.