Making Investments Where It Matters

High-End Machines, High-End Products

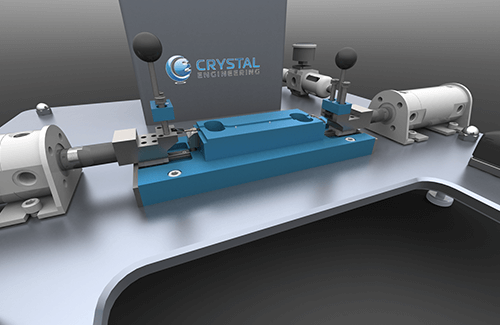

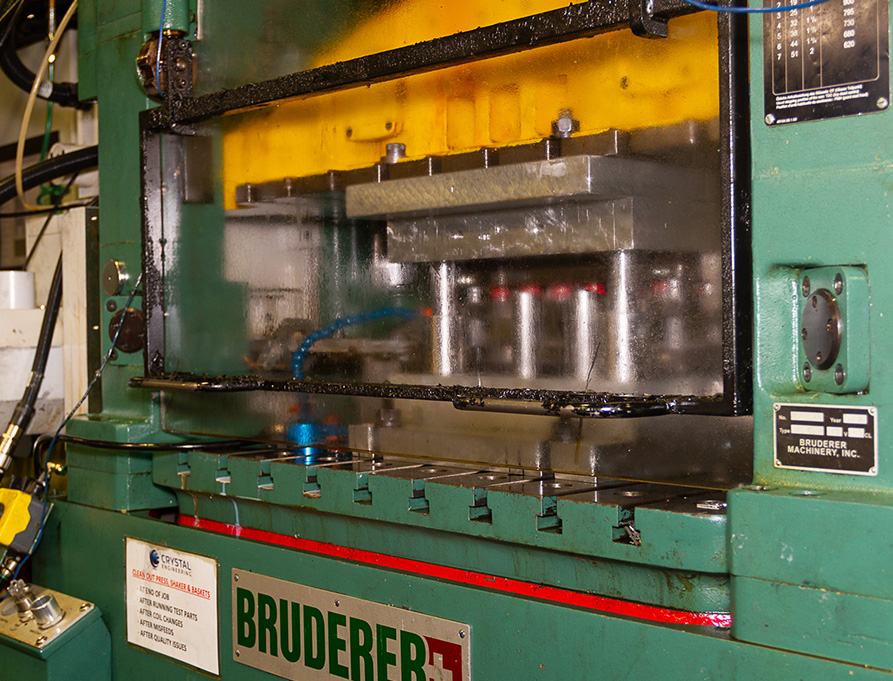

When you start with the best, your end result is going to show it. That’s why we only use the most advanced, precise, and powerful.

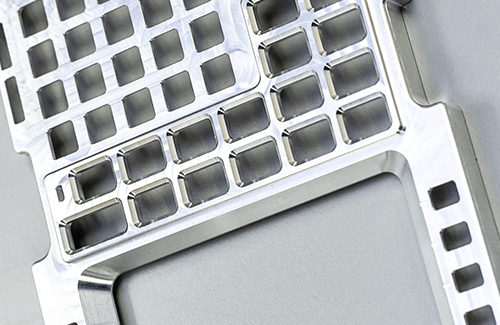

Bruderer, Charmille, Mazak, Chevalier. These are the machines we use every day. We take this stuff – your stuff – seriously. We make products marked by precision and the tightest possible tolerances, which means we can’t have shoddy, antiquated technology taking up valuable space. We are constantly on the look-out for technology that will improve our process and your product.

We’re the neighborhood machine shop that thinks and operates on a global scale. World class machines, world-class people, and world-class clients, making for world-class partnerships.

In Search of Perfection: Controls, Compliance, Cleanliness and Care

Every process we undertake includes a high degree of quality control, as well as compliance with national and international standards. Extreme care is taken to ensure the cleanliness, accuracy and precision of our parts is never compromised.

- Inspection departments monitor every project.

- Team leaders meet weekly to discuss process and product integrity.

- Aerospace 9100D, ISO 9001:2015, and ITAR compliant.

- Quality inspection tools include Micro Vu and Tesa Hite.

- Deburring via custom-made tumblers filled with biodegradable corn cob media.

- Wetting tests on all parts to verify cleanliness.

- Parts cleaned and bagged immediately to prevent contamination.

- Inspection and packaging with Nitrile gloves.

- Clean, climate-controlled environment.

Sustain Abilities

CRYSTAL ENGINEERING is concerned for our natural surroundings, on the local and global scale. We are always looking for ways to be more conscious of our role as stewards of the environment and community. When we identify a process or product that can make us “greener,” we pursue and perfect it in the most responsible way possible.

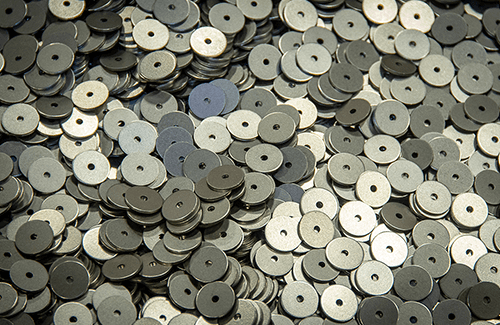

- Closed-loop stamping and milling process, with 100% of surplus recycled, amounting to tens of thousands of pounds per week of recyclable material.

- Natural, biodegradable corn cob media used for deburring.

- Solar energy to supplement our energy consumption needs and reduce our carbon footprint.

- Switched to environmentally-friendly cleaning solvent with equal or better cleaning* results.

*Based on 3M laboratory study conducted for Crystal Engineering.

We Don't Mess Around

As you walk the floor of our plant, here are some things you might find missing ... Debris, spills, dirt, scrap, grime, etc. We take great pride in keeping a clean, organized, spacious facility, because it’s safer for our employees, better for the environment, and helps us produce a superior product.